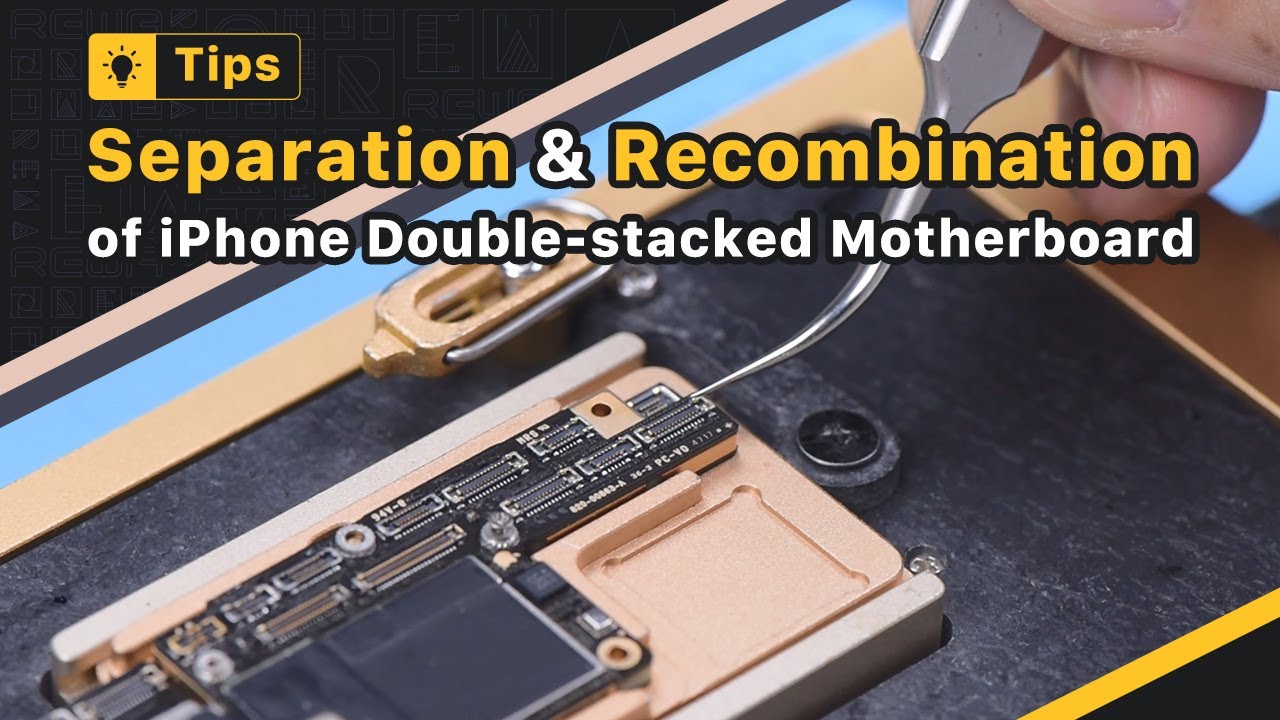

Lately, REWA Academy pupils provided responses that the two layers frequently fail to fit very closely in double-stacked motherboard repair service There are also big gaps, creating quasi soldering In feedback, we will certainly share pointers as well as notes when dividing and also recombining double-stacked motherboard Remove foam on the motherboard prior to heating Please be kept in mind that we do not recommend newbies to warm the motherboard with a warm air gun Because the motherboard might receive warm unevenly and warp A specialist motherboard heating system is what we suggest To facilitate later on elimination of the reasoning board, drive a screw on the reasoning board Cut with the tape with a Sculpture Blade The reasoning board and also middle layer are soldered with low-temperature solder paste So the most effective temperature level for the home heating platform will certainly be 155 ° C-165 ° C Push the reasoning board delicately with tweezers when the temperature level reaches 165 ° C If the logic board hangs, the tin has actually melted Clamp the screw to eliminate the logic board Get rid of the signal board Remove thermal grease with a Sculpture Blade Thermal grease have to be gotten rid of entirely Or else, the thermal grease will touch the logic board to generate pseudo soldering in recombination Attach the signal board to the holder Use a round of Paste Change Remove tin on the bonding pad with Welding torch at 365 ° C and Solder Wick Tin on the bonding pad should be entirely removed The residual tin will affect the succeeding soldering Clean the bonding pad with PCB Cleaner Clean the logic board with the exact same technique Please do not damage components around the bonding pad of the reasoning board while cleansing It is essential to check if the bonding pad is cool after cleaning Connect the signal board to the Reballing Platform Put the reballing stencil in placement to see to it that it is pushing versus the signal board To prevent the solder paste from moving into the motherboard space, place a steel plate Apply a layer of low-temperature Solder Paste Wipe off excess solder paste with a Lint-free Wipe Remove the reballing stencil Check if solder paste on the signal board is complete While using solder paste, please make sure that solder paste must have a specific humidity If the solder paste is too completely dry, it will abide by the reballing stencil when the pattern is removed Because of this, the solder paste on the signal board will certainly not be consistent, which can conveniently cause bad soldering Put the signal board on the 165 ° C Heating Platform to warmth Stop heating after the solder spheres are formed Apply a percentage of Paste Change after the signal board has cooled Align the reasoning board with the signal board Keep heating on the 165 ° C Heating Platform When the solder change spills and also reasoning board sinks, nudge the reasoning board gently with tweezers to make sure both layers fit closely The push has to be gentle and little Clean the motherboard with PCB Cleanser after the motherboard has actually cooled down If you discover the motherboard warped while recombining, you can place the motherboard on a level board and also attach it with an elastic band Press two sides of the motherboard gently To stay clear of squashing parts, please put a soft paper under the motherboard Next, we will certainly share one more recombination method The method can be taken if the middle bonding pad is not harmed When the tin thaws, remove the reasoning board in an upright way with tweezers It can be seen that there is a metal pad of 0.05 mm thickness around the signal board at a particular range This steel pad is developed to maintain a 0.05 mm void between the logic board as well as the middle layer, protecting against the solder balls from bridging while soldering You just need to get rid of thermal grease on the motherboard when the repair service is done Maintain initial tin on the bonding pad Apply a tiny amount of Paste Flux Lastly, align the logic board with the signal board When the temperature level reaches 165 ° C and the tin melts, transform the power off Press two ends of the reasoning board with tweezers up until the motherboard has actually cooled down The logic board and the signal board fit carefully by doing this There will be no connecting and also solder spheres spillover Check out REWA Academy if you intend to find out more fixing abilities We have total program plans for motherboard medical diagnosis and also fixing capacity renovation Click the web link in the comment section to buy motherboard repair training course bundles Thanks for enjoying and also feel totally free to leave a comment

iPhone X-12 Double-stacked Board Separation & Recombination | REWA Academy Tips